Evolution: Year to Year Technical Changes

*Running changes may not be applicable at date of purchase

New For 2023

Crankcase:

All new casting, improved design, precise machining

Redesigned two-piece front bearing housing, bolt-on oil squirter

Rubber gasket for reliable seal between the case and the rear bearing housing

Starter cover and crank position sensor adapter are integrated with crankcase casting

Screw-in inspection plug

Roller Tappets:

Eliminates outdated and inconsistent process of manufacturing of the old style flat head tappets in-house

Increases reliability and durability due to reduction of wear of the tappet rollers and camshaft lobes

Allows for more consistent valve clearance adjustment

CV-joints sidecar driveshaft:

U-joints are replaced with the CV-joints

Smoother rotation at all angles

Increased reliability and service intervals

New For 2021/2022

Achieving Euro5 certification is a major milestone for Ural, but what exactly has changed?

The two main challenges for Ural were emissions and noise and this became the main technical focus.

The change to Keihin EFI in 2019 paved the way for the development of the necessary upgrades to meet the very stringent demands of Euro5.

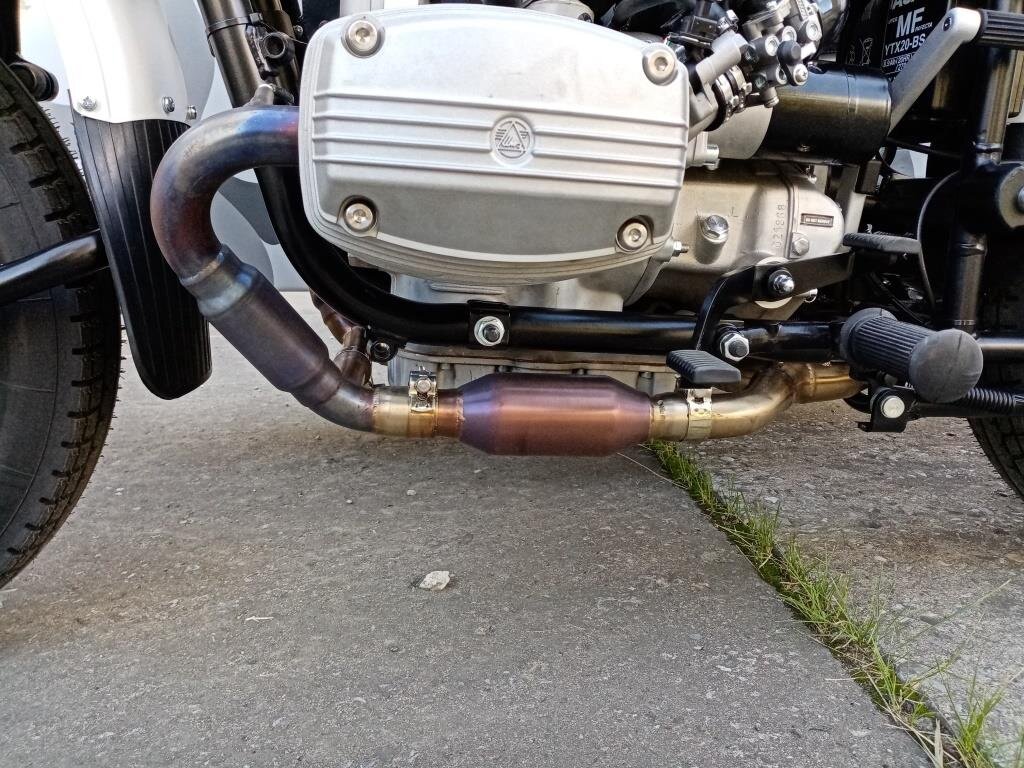

The exhaust system had to be completely redesigned and now consists of a custom built, stainless-steel, 2 into 1 system with a high-level, large single rear silencer. This significantly reduces noise and increases ground clearance as well - a welcome bonus for those venturing off-road.

The exhaust system now contains two pre-catalysts and two large diameter main catalysts. An inbuilt "vacuum valve" is actuated by engine vacuum, controlled by the ECU via a vacuum relay, giving rapid warm-up of the catalysts at low R.P.M. and full unrestricted power at higher R.P.M. The Keihin throttle bodies had to be adapted to provide vacuum take-offs to support this functionality.

The pistons were recently redesigned to increase compression ratio by 20%. They are still gravity cast from NASA388 aluminium/silica alloy - with a hard-anodised crown and top ring-groove. Various applications of high-tech coatings on the piston skirts, ring grooves and rings, as well as a phosphate coated gudgeon pin, all reduce internal friction. Precision machining and reduced tolerances all contribute to longer service life.

The centre stand has been completely redesigned to make it easier to lift and lower the bike safely - whether you're in the workshop or out on an adventure.

All of these features will be delivered as standard on 2021 model year Euro5 Urals and new Ural owners will undoubtedly benefit from this comprehensive range of mandatory technical improvements.

New 2-into-1 exhaust system with high mount silencer (Euro5 compliant)

Updated intake manifolds with barbed vacuum ports

High compression pistons

Forged aluminum front swing arm

All new rear brake system utilizing a two-piston Brembo caliper and a standalone mechanical parking brake caliper

New center stand

Heidenau Tires are now standard equipment

New For 2020

19” aluminum rims from Italcerchio S.R.L.

Forged brake caliper brackets

One-piece forged alternator adapter shaft

Bi-metal piston pin bushing

Updated swing arm and fork leg design incorporates dust seals to prolong bearing life

Improved rear sidecar body mounts "snowmen" incorporate an internal spring for increased load capacity

New For 2019

Re-designed cylinder head covers

Cooling fins increased in surface area for improved cooling efficiency

Improved piston and cylinder design

Throttle position sensor for improved throttle response.

All new EFI system utilizing Keihin throttle bodies

Improved oil pick-up design and increased oil pan capacity

Universal spare wheel

New For 2018

Spotlight replaced with high visibility LED Fog Lights on Gear Up sidecar.

New passenger windshield on cT model.

New hydraulic/gas charged steering damper.

New reed style magnetic float fuel sensor.

Three new standard paint options (Slate Grey, Burgundy Satin, and OD Green).

If you have questions about a Ural older than 2018 please contact us